making waves

Wabtec Marine (Formerly GE) has been designing and building high-performance diesel engines for over 40 years. Today, they are one of the world's leading mid-speed diesel engine manufacturers. In its V250 marine engine, the best features of previous engine designs have been combined with proven advancements to deliver efficiency, reliability and performance advantages.

V250

MDB

6.5%

Fuel savings by meeting IMO Tier II

The V250 proves that it is possible to meet IMO Tier II emission compliance requirements without sacrificing fuel efficiency. In this engine, improved fuel management, a refined combustion system design and cooling provide fuel savings of up to 6.5% compared to our previous engine designs.

25%

Higher power density in a compact design

A relatively large diameter engine with a narrow overall width and lighter weight, the V250 packs a lot of power into its footprint. Among other features, its intake and exhaust manifolds are compactly arranged between cylinder banks. Where space is at a premium, the V250's finish design and high power-to-weight ratio give it a clear advantage.

100%

Designed for reliability and serviceability

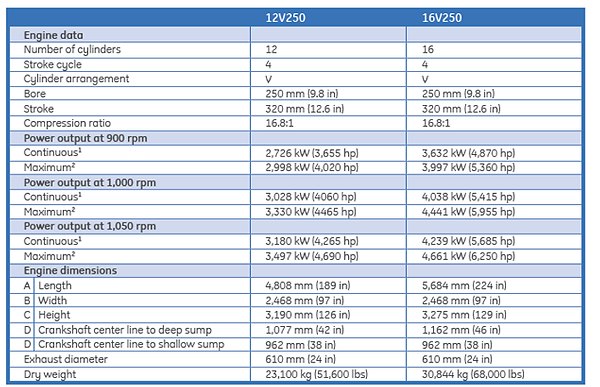

The V250 engine is designed not only for greater efficiency and lower emissions, but also for greater reliability and serviceability. Designed with in-engine accessories, all of the V250's critical components and systems have been designed, manufactured, tested, refined and extensively validated for reliability. For easier maintenance, a segmented camshaft, sectional exhaust manifold, unified power package and other features simplify component removal and replacement. With impressive features, ratings and a full power PTO, the V250 is sure to exceed your marine engine's expectations. GE's V250 diesel engines are available in 12-cylinder and V-16-cylinder configurations for medium-speed service with continuous power from 2,725 kW to 4,240 kW.

V250 ENGINE SYSTEMS

advanced EFI

Designed for greater efficiency at variable speeds and loads, the V250's electronic fuel injection features precise fuel control, increased pressure capability and refined timing. Optimization of cam profile, injection initiation, injection volumes and flows, and control algorithms have produced a relatively simple system proven to be reliable through extensive validation.

Sophisticated control

Our controller drives the fuel injection system with advanced shut-off point detection for better fuel economy and emission control. The system features enhanced diagnostics and display of all engine parameters and faults, without the need for a laptop. Engine protection algorithms predict problems in advance to prevent engine damage.

robust mainframe

The main frame of the V250 engine features a high strength ductile iron construction. Main and connecting rod support capability provides greater reliability and durability, and improved ribs in the cross bolt area increase rigidity and decrease vibration.

High efficiency turbocharger

We took a proven turbocharger design and leveraged the aerodynamics expertise of our aviation business to improve it. Higher bearing resistance, better rotor dynamics, a cooled housing and integrated packaging create a high-performance, high-reliability system. The turbocharger combination optimizes performance for various speed ratings.

heavy duty crankshaft

Forged from high quality steel and nitride hardened for long life, the crankshaft of the V250 has a one-piece construction with no bolt-on joints. Large trunnion surface areas minimize loads and dynamically balanced counterweights reduce stress for longer crankshaft life.

OPERATIONAL ADVANTAGES

Improved power sets

Our redesigned power package meets the high pressure demands as well as the stringent reliability requirements of the V250 engine while maintaining an easy to maintain assembly concept. The unit's refined flow path enhances combustion, fuel economy and reduced emissions.

one-piece liners

"Stiff", "one-piece" and "mid stop liner", features an integrated external water jacket that removes the possibility of water leaks. An anti-polishing ring provides a durable running surface, improving oil consumption and liner life. The "top one third" of the liner is cooled.

Robust cylinder heads

A one-piece casting, fully supported head gasket wall structure, thicker flame deck, and resizing and relocation of the cooling holes significantly improves the strength and margins of the assembly's cylinder head design.

piston design

Our piston design meets the increased weight and pressure requirements of the V250 engine. Improved skirt and pin protrusion provides better lubrication and guidance. With dynamics optimized through secondary motion analysis, the piston design reduces oil consumption, reduces blowby and extends oil life.

forged connecting rods

Exceptional strength, high rigidity and large bearings are unique features of our connecting rods. Large bearing width and optimized oil groove in bearing housing improve oil film thickness and pressure.

segmented camshaft

The V250 camshaft is organized into individual sections for easy inspection and maintenance. Forged and hardened camshaft lobes reduce wear. Oversized bearings lessen loads to extend camshatf life.

Better fuel efficiency

Higher power density

Improved reliability and serviceability

They're all aboard

It's all here - in the technologically advanced, fuel-efficient and environmentally compatible diesel engine built by Wabtec Marine (formerly GE).

It is the product of more than six years in development and testing and nearly six million megawatt hours in service.

And with customization for the marine industry and competitive pricing, it's ready to meet your marine energy needs.

The V250 diesel engine. Wabtec Marine's (formerly GE) experience, innovation and proven performance reduce your cost of operation.

V250 MDB engine specifications